Machine Vision vs Computer Vision: The Differences & Why It Matters

Matroid | January 9th, 2024

In the world of manufacturing and other industries, the term “machine vision” is often used interchangeably with “computer vision.” While both concepts involve the use of technology to interpret visual data, they are not one and the same.

Modern advancements in technology have given rise to a more sophisticated and powerful approach known as Computer Vision. In this post, we’ll explore the key distinctions between Machine Vision and Computer Vision and why these differences matter, particularly for operations leaders and organizations that prioritize safety and security.

The Evolution of Machine Vision and the Emergence of Machine Learning

Machine Vision, in its basic form, has been a fundamental component of various industries for a few decades. This concept involves the use of computer systems to capture, process, and analyze visual data, aiding in quality control, defect detection, and other critical tasks.

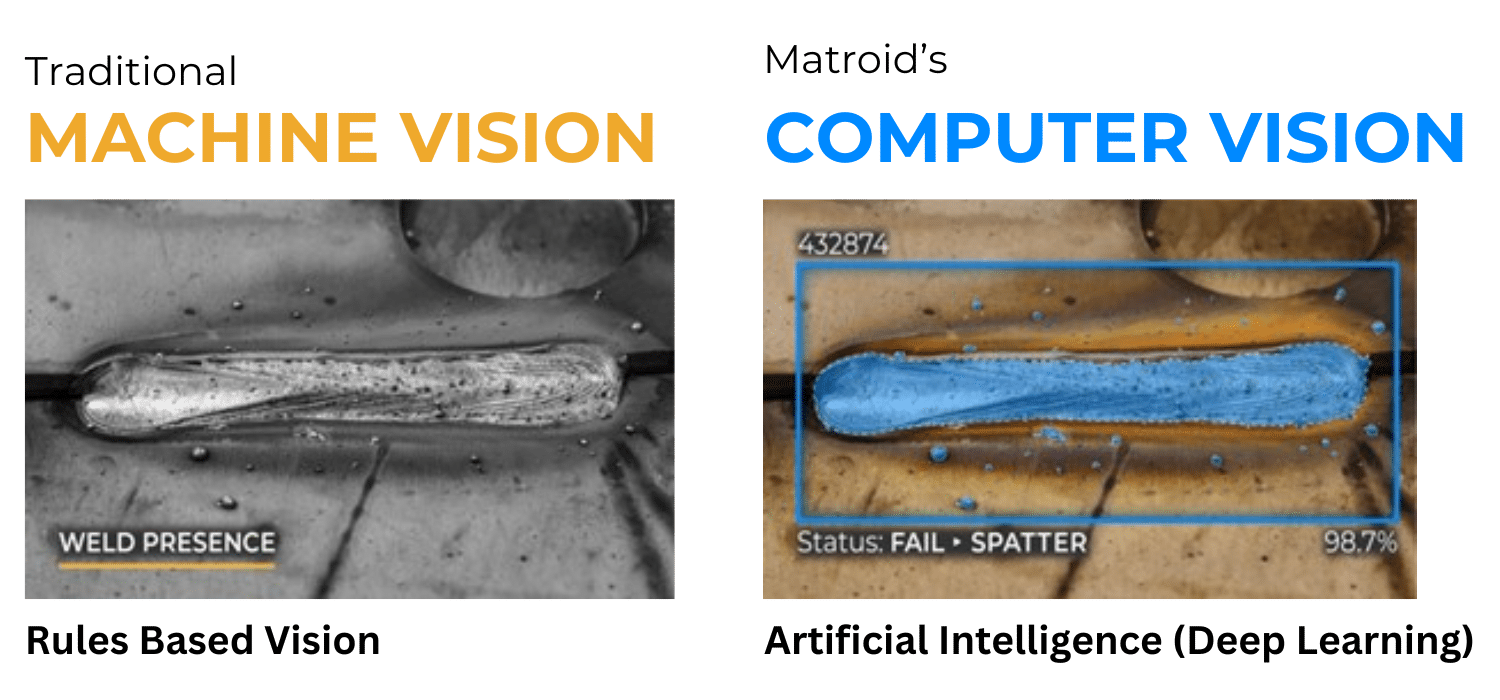

These systems rely on predefined rules and algorithms for image processing, such as specifying product features like size, shape, or color in manufacturing. This approach also demands prior knowledge of object and scene characteristics. Traditionally, machine vision is used for specific, well-defined tasks like object or feature presence/ absence, defined by grayscale edge and blob tools. While reliable for accurately defined tasks such as measurement, machine vision struggles in variable environments.

This is why Computer Vision, particularly AI-based Computer Vision, is emerging as a more powerful and versatile choice. This technology can learn and adapt to visual data, making it suitable for a wider range of applications and scenarios.

Rules-Based Machine Vision vs. AI-Based Computer Vision

One of the most significant differences between Machine Vision and Machine Learning lies in their underlying principles:

Rules-Based Machine Vision:

In the domain of rules-based machine vision, systems operate on a foundation of predetermined rules and algorithms to scrutinize and comprehend images. The user plays a crucial role in this process, meticulously positioning a camera and adjusting lighting conditions. By precisely defining rules based on factors such as the camera’s exact position and the presence of reflections and shadows at that specific moment, the system becomes adept at analysis.

These rules typically encompass parameters like edges and blobs of pixels, relying on contrasts and grayscale values for interpretation. For instance, when detecting the presence or absence of an O-ring on a machined part, the camera, accompanied by external lighting, captures a distinct arrangement of dark pixels within a precisely defined area. This pattern remains consistent as long as the part remains stationary, or it alters to a set of illuminated pixels when the O-ring is absent.

There are a variety of factors that challenge rules-based systems, such as in scenarios involving high-mix production. Using the example of the O-ring inspection, alterations in the shades of black, changes in material with a glossy or reflective finish, or variations in color can disrupt the rules-based system.

Any deviation in inspected components, whether related to color, texture, shade, shape, or size, can lead to a breakdown in the rules, rendering the system unreliable.

AI-Based Computer Vision:

AI-Based Computer Vision takes a fundamentally different approach from rules-based machine vision, harnessing the power of artificial intelligence and deep learning techniques. In this paradigm, tools like convolutional neural networks (CNNs) and recurrent neural networks (RNNs) are employed to enable systems to learn and adapt to visual data dynamically.

CNNs, functioning akin to a meticulous magnifying glass, dissect images bit by bit, excelling in the recognition of edges, corners, and textures within pictures. While RNNs specialize in comprehending sequences of data. In stark contrast to rules-based systems that rely on predefined guidelines, AI-based computer vision systems acquire knowledge by discerning patterns and features directly from the data they encounter.

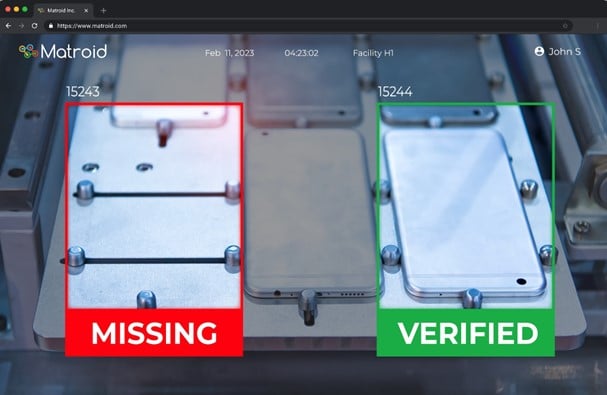

In this realm of deep learning, the system learns in a manner similar to how a new machine operator is trained in a manufacturing environment. Here, the manufacturing expert provides examples of the desired system outputs to the AI. For instance, a weld engineer who wants to automate the detection of various defective weld conditions, such as porosity, spatter, or incomplete welds, would showcase examples of each to the AI system. The computer vision system then “learns” from these examples, effectively defining rules based on the variations and instances. This dynamic learning process allows for a much more adaptive and nuanced approach.

Flexibility in Machine Learning: Adapting to Change

Rules-based machine vision systems are like well-structured routines, but they come with limitations. They’re rigid, demanding manual adjustments or reprogramming when the application or environment changes. These systems find it tough to tackle complex or unstructured data.

In contrast, machine learning systems are akin to adaptable problem solvers. They effortlessly handle a wider variety of visual data and can adapt seamlessly to changes in the environment without needing human intervention.

Computer vision, in essence, can tackle intricate tasks and decipher complex patterns that might pose challenges for rule-based systems. It signifies a shift from manual feature crafting to holistic learning, where the system learns both feature extraction and task execution. This has applications across various domains, from healthcare to aviation and security, excelling in image and video analysis, object recognition, and scene understanding.

Training with Computer Vision: Learning from Data

While rules-based machine vision systems offer initial simplicity because they don’t require extensive training, there is a deficit because human experts design the rules and algorithms. Therefore, the systems which operate on those predefined rules can be inflexible, requiring manual rule adjustments. This can lead to delays and increased costs.

In contrast, AI-based computer vision systems undergo extensive training on large datasets, making them adaptable and intelligent. They can identify not just predefined features but also unexpected variations and anomalies.

This adaptability is crucial in dynamic manufacturing, where specifications change. AI-based systems are well-suited for tasks like quality control, defect detection, and process optimization, enabling enhanced efficiency and product quality without manual intervention.

Scalability in Machine Learning: Meeting the Demands of the Future

Scalability is another area where AI-based computer vision has the upper hand. What can be time consuming – and expensive – with rules-based machine vision systems is creating and maintaining rules for new applications. Experts must painstakingly design, test, and fine-tune these rules to ensure their effectiveness.

On the other hand, computer vision presents a more flexible and cost-effective solution because the systems can be retrained to adapt to new tasks or domains with relative ease. They achieve this through techniques like transfer learning and fine-tuning.

Transfer learning allows AI-based systems to leverage the knowledge and patterns they’ve acquired from one task or domain and apply it to new, related tasks. This not only expedites the adaptation process but also reduces the resources required. And fine-tuning enables the system to specialize and refine its knowledge on specific aspects of the new task, ensuring even greater accuracy.

This adaptability gives manufacturing companies a competitive edge, as they can swiftly respond to shifting market demands and diversify their product lines while minimizing additional expenses and reducing time-to-market.

Performance with CV: Handling Complexity and Diversity

Performance is an important consideration in the interpretation of visual data and there is a noticeable contrast between rules-based and machine learning approaches.

Rules-based machine vision excels in well-defined, controlled scenarios, operating like experts in a controlled laboratory with precise instructions. In such settings, these systems can reliably inspect product surfaces for defects and verify assembly. However, they falter in unstructured situations, where diverse visual data poses challenges, like changing lighting conditions or unexpected anomalies in manufacturing.

AI-based computer vision adapts and learns continuously from data and thus outperforms rules-based counterparts in diverse environments. Where product designs evolve and lighting varies, AI-based systems promptly adjust, recognizing unprogrammed patterns and anomalies, enhancing product quality and reducing false alarms.

Error Handling: How Machine Learning Deals with Uncertainty

Because rules-based machine vision systems operate based on predefined rules, the system must encompass all potential scenarios comprehensively. If these rules fall short or if the environment undergoes unexpected changes, the system may fail.

In such cases, pinpointing the source of errors, debugging, and maintaining rules-based systems can consume valuable resources and lead to production delays and quality issues.

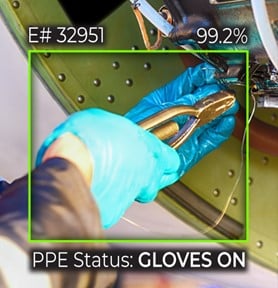

AI-based computer vision systems exhibit remarkable resilience in the face of data uncertainty because they are equipped to handle and even learn from errors. When faced with ambiguous situations, AI-based systems don’t simply break down; instead, they provide confidence scores associated with their decisions. These scores indicate the system’s level of certainty, offering valuable insights for decision-makers.

This feature is especially crucial in industries where the consequences of errors can be costly, such as healthcare, aerospace, and security.

In conclusion, it is important for operations leaders to understand the distinctions between Machine Vision and Computer Vision. Matroid’s advanced Computer Vision system offers real-time insights throughout the entire lifecycle of CV implementation, spanning from development and testing to deployment and management. Matroid’s comprehensive approach to Computer Vision is also distinguished by its coding-free design, which eliminates the need for coding expertise.

As the industrial landscape continues to evolve, the choice between Machine Vision and Computer Vision will remain a pivotal factor in determining the success and efficiency of various industries. Experiencing a demo from Matroid is a great way to witness the power and capabilities of computer vision technology firsthand.

Download Our Free

Step By Step Guide

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today