Computer Vision in Metal Forming: Precision, Efficiency, and ROI

Matroid | October 8th, 2024

As the metal forming industry evolves, staying ahead means embracing cutting-edge solutions like computer vision (CV). Traditional methods can’t keep up with the speed and precision needed today. Enter Matroid’s AI-powered CV: your solution for real-time defect detection, precise alignment, and proactive maintenance.

Discover how Matroid’s CV can transform your operations:

- Identify Defects Instantly: Slash defect rates and improve product quality.

- Achieve Perfect Alignment: Ensure components fit flawlessly every time.

- Monitor Equipment: Prevent breakdowns before they happen with predictive maintenance.

Unlock the full potential of your metal forming processes with CV, driving efficiency, enhancing safety, and delivering substantial ROI. Here’s a closer look at how these advancements can address your toughest challenges and elevate your business performance.

Problems Solved by Matroid’s Computer Vision in Metal Forming

Eliminate Incomplete Fills with Matroid’s Real-Time CV

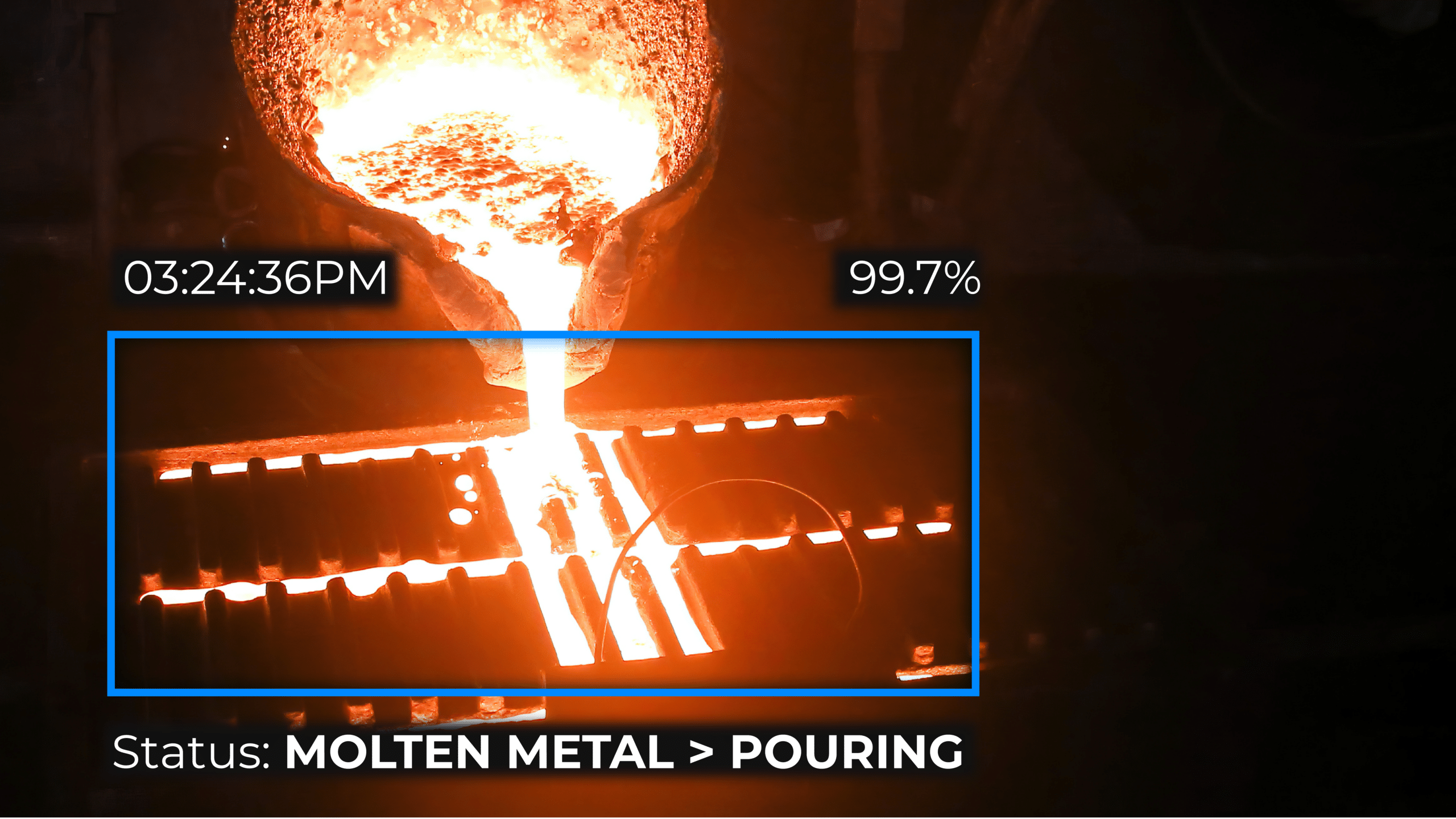

Problem: Failure to fill happens when molten metal doesn’t fully fill the mold, leading to weak or defective components that jeopardize quality and performance.

Matroid’s Solution: Our CV technology detects incomplete fills instantly during casting. With advanced imaging and machine learning, Matroid identifies fill issues in real-time, enabling immediate operator intervention. Ensure every component meets your quality standards with Matroid’s precision and speed.

Keep Your Production Pristine with Matroid’s CV for Filter Inspection

Problem: Broken filters can cause contamination and defects, but spotting them manually is slow and prone to error.

Matroid’s Solution: Our advanced computer vision system continuously scans filters for damage with high-resolution cameras and powerful image processing. Detect broken or malfunctioning filters instantly to ensure only top-quality products reach the market. Boost product standards, reduce waste, and streamline your quality control with Matroid’s precision.

Combat Hot Tears with Matroid’s Real-Time CV

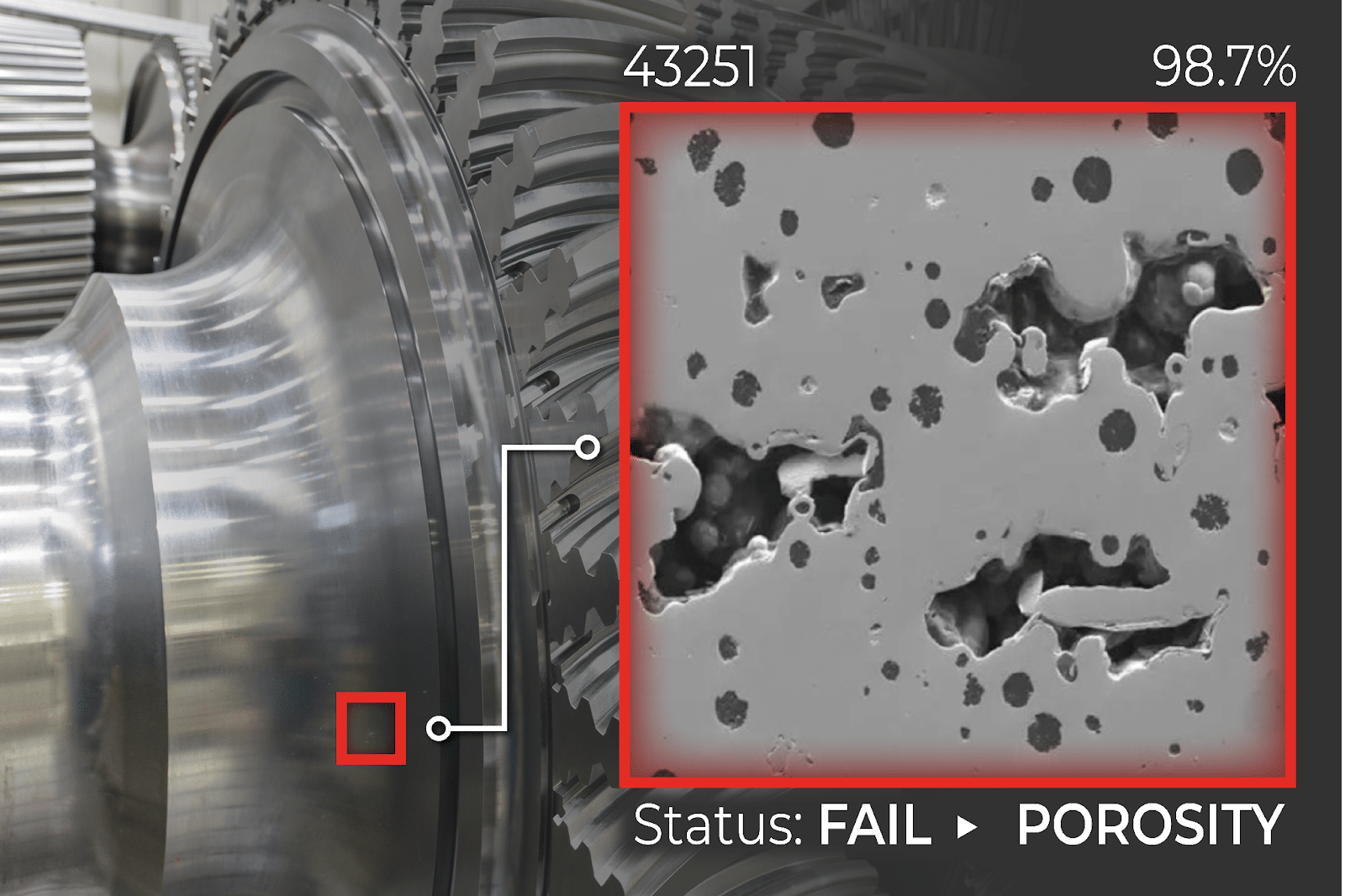

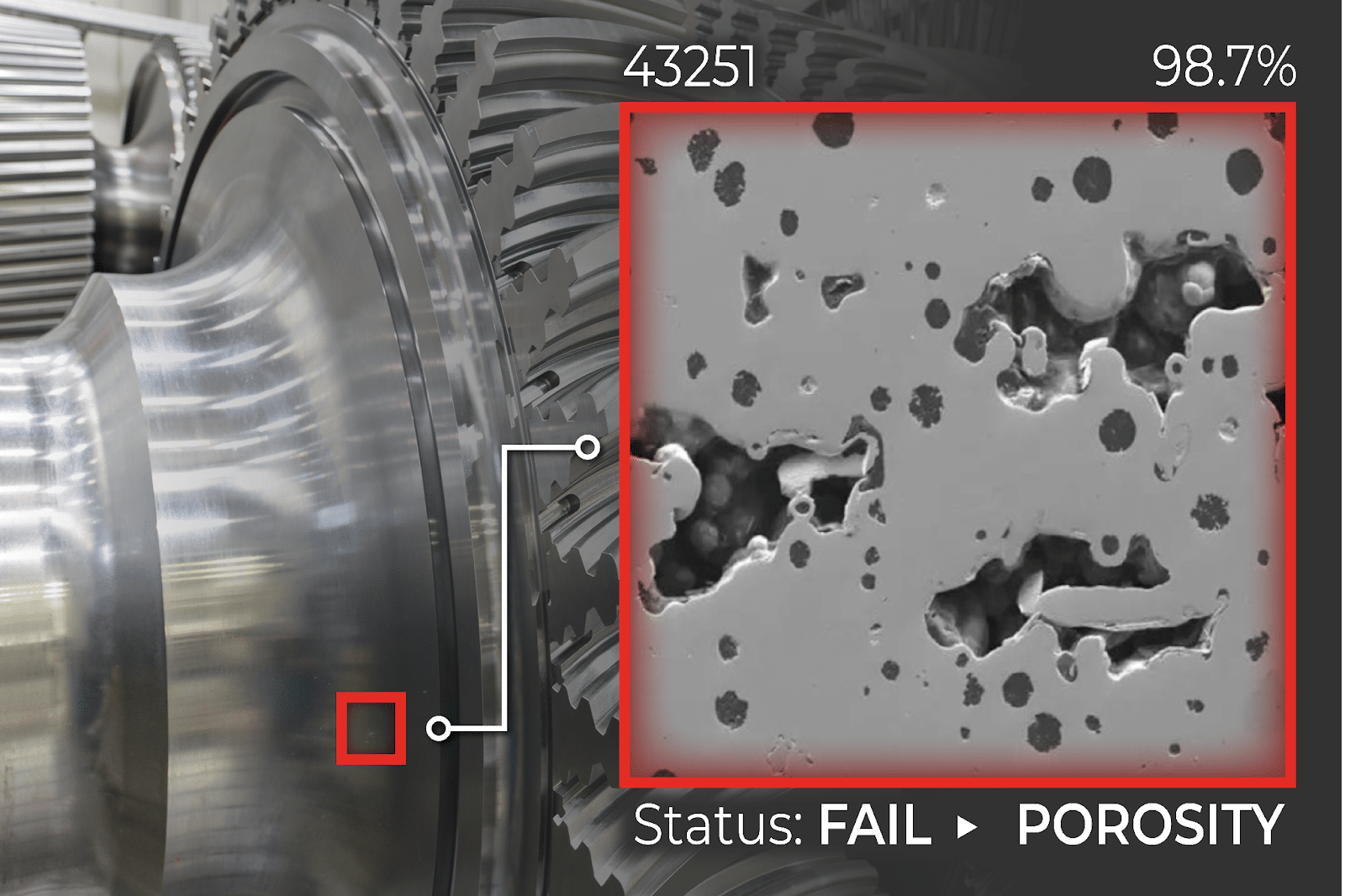

Problem: Hot tears occur during metal solidification, causing cracks that undermine product integrity and lead to costly waste.

Matroid’s Solution: Our state-of-the-art computer vision system detects hot tears in real-time by measuring density and area fraction of these defects. Immediate identification allows you to address issues on the spot, improving product quality, reducing waste, and cutting costs. Enhance your metal forming operations with Matroid’s CV for better economic efficiency and safety.

Secure Your Facility with Matroid’s Gas Leak Detection

Problem: Gas leaks in metal forming facilities can lead to explosions, fires, and toxic exposure, endangering workers and disrupting production.

Matroid’s Solution: Our CV software provides continuous monitoring using infrared and thermal imaging to detect invisible gas leaks. With instant alarms and automatic shutdowns, Matroid ensures swift action to prevent accidents, maintaining a safe environment and avoiding costly production halts. Enhance safety and operational continuity with Matroid’s cutting-edge gas leak detection technology.

Safeguard Operations with Matroid’s Fire Detection System

Problem: In metal forming, high temperatures and flammable materials elevate fire risk, making early detection crucial.

Matroid’s Solution: Our visual inspection uses cutting-edge sensors and algorithms to spot early signs of fire, like smoke or unusual heat. With early detection, you can quickly intervene to minimize damage, protect equipment, and ensure personnel safety. Stay ahead of potential fires and secure your operations with Matroid’s fire detection technology.

Spot and Fix Issues Early with Matroid’s Anomaly Detection

Problem: In metal forming, unexpected anomalies like temperature swings, abnormal vibrations, or component irregularities can signal production issues that threaten quality and efficiency.

Matroid’s Solution: Our CV leverages machine learning to understand normal operational patterns and detect deviations. By identifying anomalies early, Matroid helps you address minor problems before they escalate, ensuring consistent production quality and optimal efficiency.

ROI Impact of Vision Systems for Manufacturing

Implementing computer vision (CV) in metal forming operations delivers significant ROI through enhanced efficiency, cost savings, safety, and product quality.

Increased Efficiency: With real-time detection, CV systems swiftly address incomplete fills and defects, minimizing waste and reducing the time spent on corrections. Automated quality inspections further streamline the process by eliminating manual checks, thereby accelerating production cycles. The result is faster production, higher throughput, and substantial time savings

Cost Savings: CV systems drive cost savings by reducing defects, which lowers expenses related to rework, scrap, and warranty claims. By catching defects before products reach customers, companies save on buybacks, labor, and shipping fees. Additionally, early detection of gas leaks and fires minimizes production interruptions. The result is improved financial performance and reduced operational costs.

Improved Safety: CV systems enhance safety through proactive hazard monitoring, continuously tracking for gas leaks and fires to prevent accidents and injuries. This leads to lower insurance premiums by reducing costs associated with workplace incidents and improving overall safety. Additionally, reduced downtime from safety-related shutdowns ensures smooth operations. The result is enhanced employee morale, increased productivity, and reduced insurance costs.

Enhanced Product Quality: CV systems ensure rigorous quality control, maintaining high standards that boost customer satisfaction and loyalty. Consistent product quality helps build a strong brand reputation, attracting new customers and allowing for premium pricing. The result is a stable revenue stream, improved market positioning, and sustained business growth.

Experience the Revolution with Matroid’s CV in Metal Forming

Companies who are using Matroid’s CV technology report improved quality control and optimized operational efficiency. Want to know why?

Our user-friendly, no-code platform empowers engineers and supervisors to easily create and refine custom detectors using annotated data. With an intuitive interface and automated detector updates, continuous quality enhancement is seamless. Plus, Matroid’s flexible machine learning integrates effortlessly with your existing or new camera systems, elevating safety and compliance.

Stay ahead of the competition, meet industry demands, and optimize your operations with vision systems. Schedule a demo with Matroid to explore the transformative impact of CV technology in metal forming.

Download Our Free

Step By Step Guide

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today