AI in Manufacturing: A Partner, Not a Replacement

Jeff Zeller | April 1st, 2025

Aim for AI that works with you

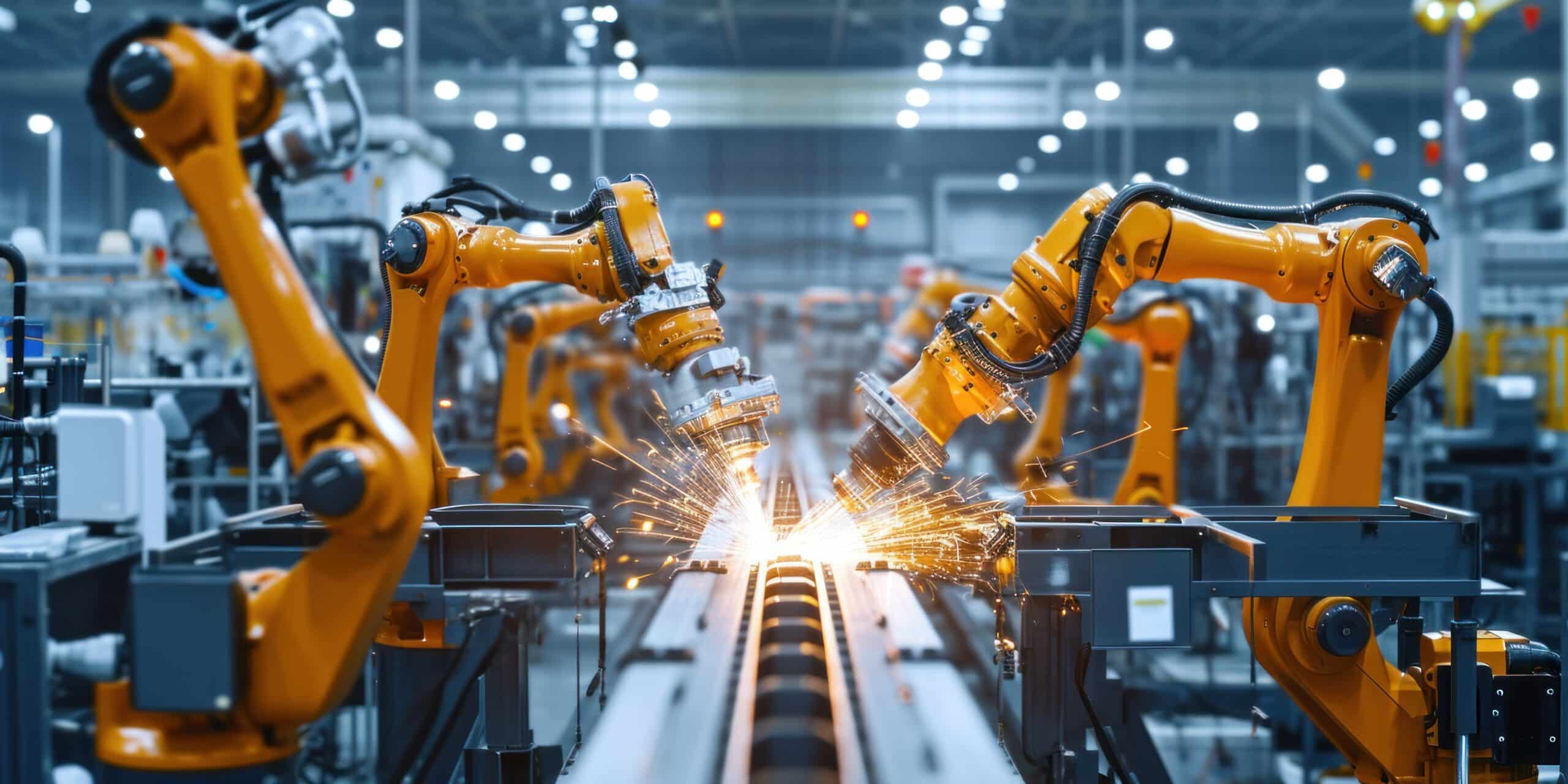

When people hear “AI in manufacturing,” they often imagine automation replacing jobs, machines making decisions independently, and factories running without human oversight. The reality is far less dystopian and far more exciting.

AI isn’t here to replace the people who keep manufacturing moving. It’s here to help. AI enhances decision-making, improves safety, and makes quality control more reliable and traceable.

If you work in manufacturing, you already know how much experience, skill, and judgment go into the job. Catching a defect in a moving production line isn’t just about having sharp eyes—it’s about understanding context, materials, and processes.

AI can’t replace that expertise. However, it can act as an assistant, tirelessly scanning for issues, flagging potential problems, and providing better information so you can focus on what matters: making the best possible product safely and efficiently.

AI is supposed to make your job Easier, not Replaceable

Manufacturing is full of challenges that humans have tackled for decades. These include spotting a speed tear in an aluminum extrusion before it gets shipped to a customer, checking that every bolt is in place on a vehicle assembly line, and ensuring workers follow safety protocols, even when rushing to meet deadlines.

None of this is easy, and mistakes, reworks, and accidents are expensive.

AI’s role isn’t to take over these tasks. Its role is to assist in making inspections faster, more reliable, and less stressful.

- It doesn’t get tired. No matter how many hours it’s been scanning, it won’t miss a crack or a misplaced component because of fatigue.

- It sees patterns humans may miss. Subtle variations in weld quality or a mistake in a torquing sequence might go unnoticed until they cause real problems. AI catches them early.

- It works alongside humans, not instead of humans. While AI flags potential issues, people are still making decisions, using their expertise to determine what is a legit concern and what is not.

Instead of replacing jobs, AI makes manufacturing jobs more enjoyable and rewarding. It reduces the time spent on repetitive inspections, allowing more time to solve real problems, improve processes, and focus on innovation. Fundamentally, AI is a tool that enhances human capabilities, not a replacement for them, and it lets manufacturers do what they want to do the most—build more things!

Human-AI Partnership in Action

We’ve already seen what happens when AI is brought into manufacturing environments, not to replace people but to work with them.

- Steel manufacturers who once relied on manual inspections have AI-powered systems that flag defects with over 98% accuracy. The result? More reliable quality control and operators who can focus on fixing issues instead of searching for them.

- Automotive production lines use AI to check for missing bolts, misaligned components, improperly installed trims, and other mistakes, flagging them for human operators to fix. While AI speeds up inspections, human judgment and interaction are still at the core of the process.

- Safety monitoring has become smarter, reducing workplace accidents by flagging real-time risks. AI doesn’t enforce rules; it acts as a second set of eyes, helping supervisors keep their teams safe without micromanaging.

In all of these cases, AI isn’t replacing skilled workers—it’s giving them better tools.

Accuracy Over Automation

There is a common misconception that AI’s aim in manufacturing is purely automation. However, the real value comes from reliable accuracy.

It’s not about replacing human inspectors with machines—it’s about making inspections more reliable.

A trained human inspector might catch 96 out of 100 defects, but an AI-powered inspector ensures that the four that would be missed are caught. That doesn’t mean people are any less skilled… it just means we’re all human.

In manufacturing, where precision is everything, having AI as a backup means fewer recalls, fewer reworks, fewer production delays, and a level of consistency that simply wasn’t possible before.

AI doesn’t replace human craftsmanship. It protects it.

The Future of AI in Manufacturing: People First

There’s a common fear that AI will replace humans in manufacturing. However, AI can’t replace the experience, skill, and judgment of human expertise and knowledge of production processes. In reality, the future of AI in manufacturing is humans and AI working together, each doing what they do best.

Imagine a world where:

- Workers don’t have to spend hours on tedious inspections. AI can scan and flag potential issues, allowing skilled professionals to focus on fixing problems rather than just searching for them.

- Factories run more efficiently with increased insights. AI can gather information on previously unnoticed trends, activities, and inefficiencies, allowing human teams to gain insights and make better decisions faster.

- Safety is improved by catching potential hazards. AI can help workers stay protected without slowing them down.

That’s the promise of AI in manufacturing. It’s not a replacement but a tool, a partner, and an extra pair of eyes in an industry where precision, safety, and efficiency matter more than ever.

Bringing AI onto the Factory Floor

For AI to truly reach its potential in manufacturing, it needs to be practical, accessible, and easy to integrate into existing workflows. It’s not about flashy technology—it’s about solving real problems in real environments.

The best AI solutions don’t require workers to change their methods. Instead, they integrate with existing manufacturing SOPs, providing an extra layer of accuracy, insight, and reliability.

At Matroid, we focus on making computer vision AI work for manufacturers. Our technology is purpose-built to integrate natively with existing production, helping detect defects, ensure quality, and improve workplace safety—all without disrupting the way producers produce.

And to me, that’s why the future of AI in manufacturing is so exciting.Not because machines are going to take over. Because with AI, humans will be more capable than ever.

About the Author

Jeff Zeller is the Director of Growth at Matroid. In his free time, he’s either traveling somewhere new, planning a trip somewhere he’s never been, or eating something weird.

Download Our Free

Step By Step Guide

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today