How Matroid’s AI Computer Vision Can Transform Workplace Safety

May 15th, 2024

Summary

In a pioneering collaboration with Service Center Metals (SCM) – an aluminum extrusion and billet company – Matroid’s AI Computer Vision (CV) technology emerged as a powerful force in reshaping workplace safety. As part of a National Safety Council (NSC) Safety Innovation Challenge, Matroid aimed to proactively detect critical safety issues, particularly those associated with airbag compliance and fall risks during metal handling at SCM’s shipping and receiving docks.

Matroid’s Computer Vision Benefits in Action

In response to the critical issue of falls from height that constituted 14% of fatal workplace injuries in 2021, with costs reaching $167 billion (Bureau of Labor Statistics, 2022), the project’s goal was to detect safety hazards during the loading process, where workers operated at heights up to ten feet.

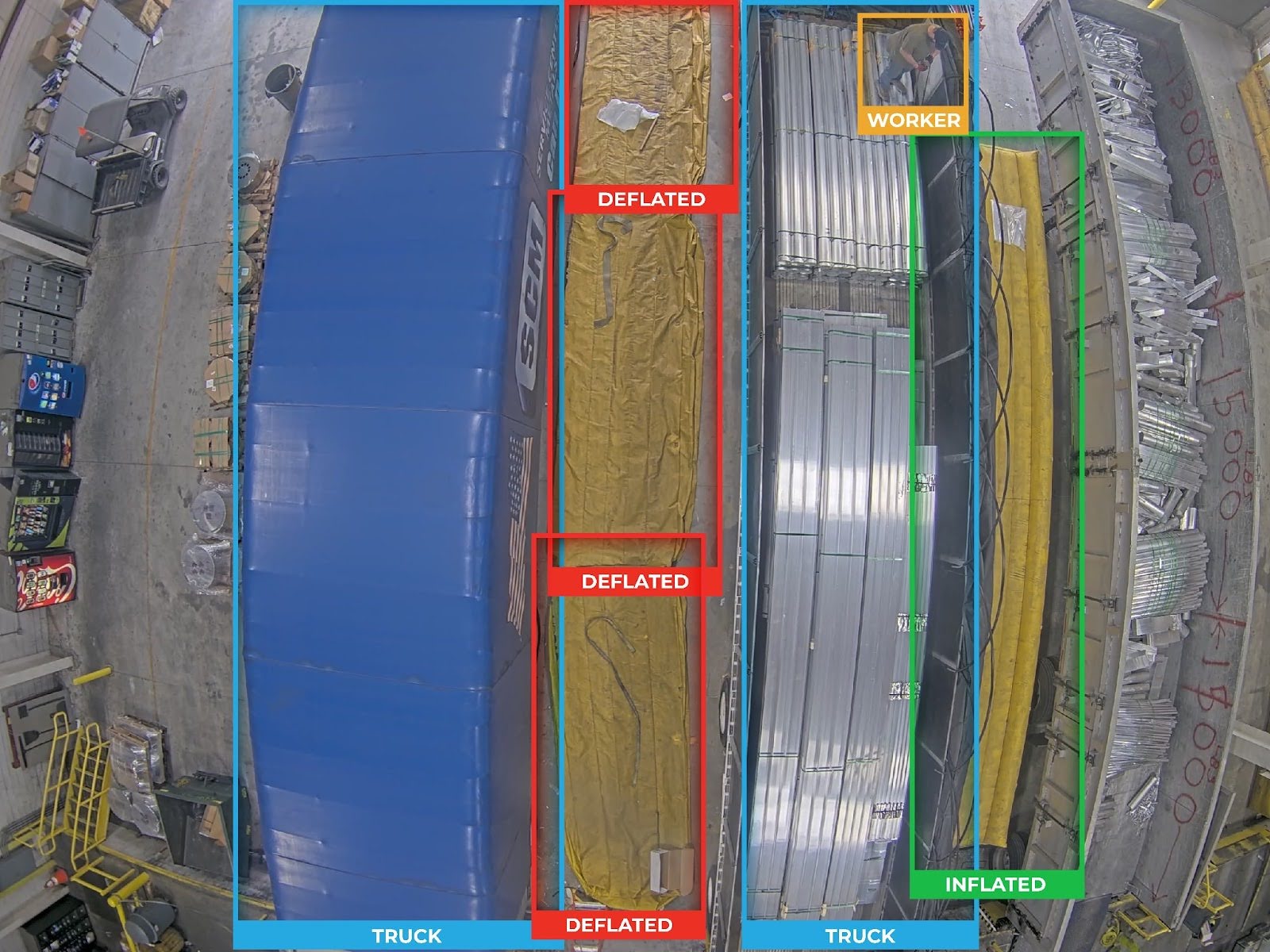

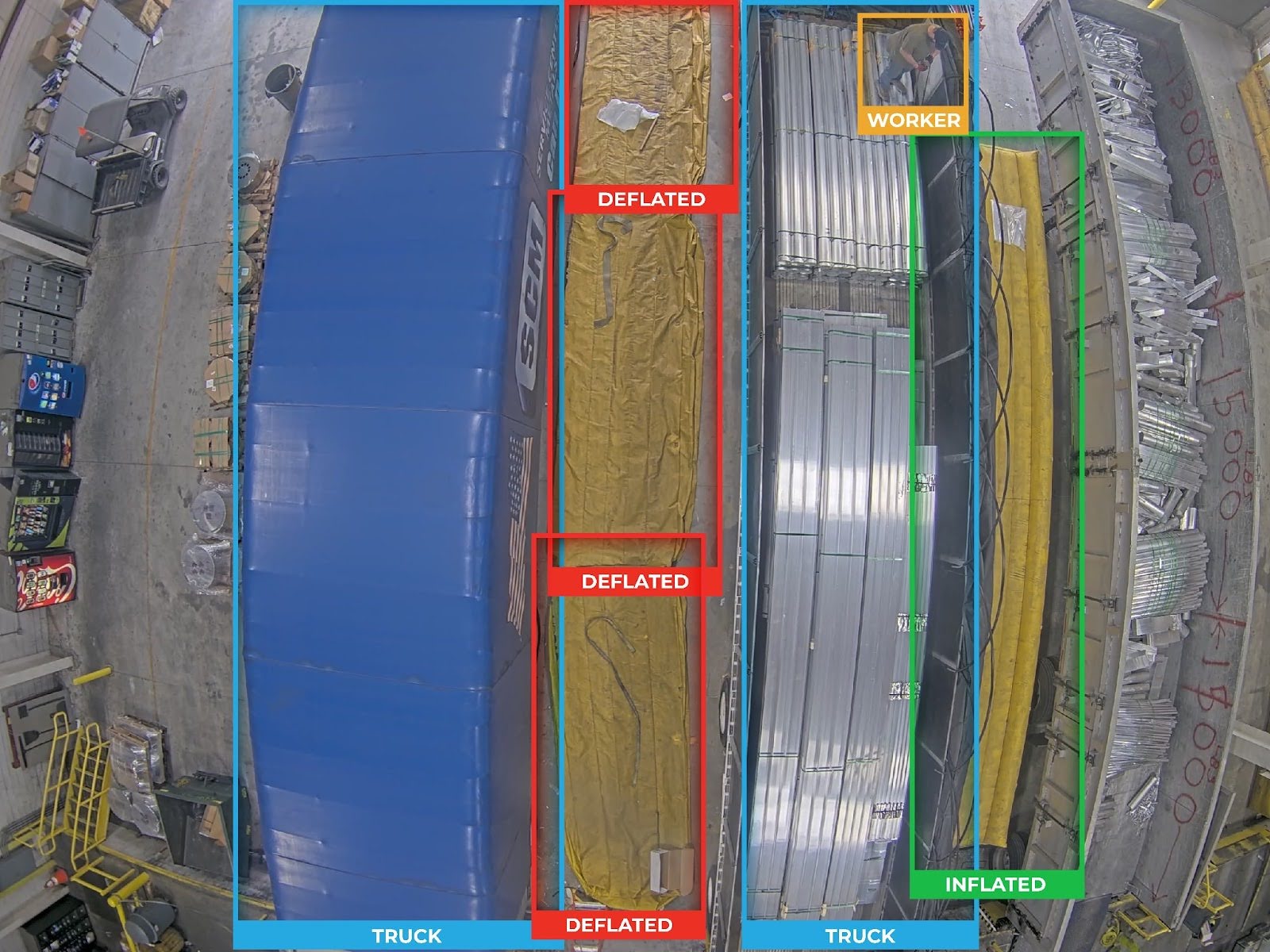

Matroid’s CV technology was leveraged within SCM’s shipping and receiving docks to detect damaged, deflated, or missing airbags meant to break potential falls during the loading process. Matroid efficiently trained its Computer Vision AI using SCM’s existing Axis video security cameras.

In just a matter of hours, the system was able to identify safety issues by analyzing a few hours of recorded video from various truck bays. It activated alerts only when a truck was present in the loading bay.

Seamlessly integrated into SCM’s existing infrastructure, the Matroid solution proved versatile, extending beyond the initial challenge. Its proactive detection capabilities not only addressed airbag compliance but also proved effective in identifying risks associated with working at height.

Moreover, Matroid’s capability to provide data for informed decision-making and dashboard creation added an extra layer of value, enhancing its role in optimizing safety measures and operational insights.

Matroid’s Computer Vision significantly improved daily airbag compliance rates, surging from below 25% to consistently surpassing 90% daily compliance throughout the pilot. The system detected almost 100 instances of improperly deployed airbags, triggering 253 violations across five bays, prompting immediate alerts and safer operations.

Matroid’s Wide-Ranging Safety Applications

Matroid’s collaboration with Service Center Metals (SCM) not only tackled the primary challenge of airbag compliance but also revealed several additional benefits with wide-ranging implications for various industries. The byproduct of automating detections allowed SCM workers to shift their focus from airbag-related concerns to other critical safety areas.

The biggest outcome of this was a substantial 400% increase in unsafe observations in shipping docks which Matroid’s CV technology was able to address effectively. A year out from the initial proof of concept, compliance rates are over 95%, and there have been zero safety incidents since implementation. The additional gains and enduring positive outcomes highlight Matroid’s broader impact on workplace safety awareness, improving the culture and positively influencing worker behavior.

Matroid’s platform showcased its versatility beyond airbag compliance, with SCM leveraging the technology to correlate packers per station with fatigue-related injuries and identify potential fire risks, such as individuals or propane tanks near open furnace doors.

Matroid Support for Facilitating Rapid Implementation

The pilot project with SCM illuminated the non-linear nature of technology adoption, offering lessons that companies can use as a blueprint for successful implementation. Through collaborative planning with the Matroid team, companies can circumvent potential hurdles to swiftly harness the power of CV.

During the pilot phase, Matroid helped navigate adoption barriers by prioritizing transparent communication, securing employee buy-in, and conducting ROI assessments. Successful CV implementation depended on securing employee support, which required taking proactive steps to address concerns about privacy, potential consequences, or fears of job displacement.

Understanding initial costs for technology installation or upgrades ensured smooth integration and optimal CV performance. Matroid works closely with companies on the front end to create custom plans in line with their budget.

The project underscores the practical importance of utilizing software to ease the workload on internal teams. Matroid’s proven agility in supporting customer implementations fostered a responsive partnership that was able to adapt to evolving organizational needs. This adaptability extends to CV itself, swiftly integrating new data, optimizing algorithms, and evolving performance over time.

Using AI-powered Computer Vision not only boosted operational efficiency but also freed internal teams to concentrate on core business activities instead of getting bogged down in operational details.

Seeing is Believing: Demo Matroid Today

Matroid’s partnership with Service Center Metals (SCM) didn’t just improve workplace safety—it demonstrated how the wide-ranging benefits of AI Computer Vision can improve worker safety in various industries. Whether a company aims to address challenging defects, incidents, actions, or events, Matroid’s technology has the capability to detect anything that is visible.

The versatility of Matroid’s CV pioneered by Matroid makes it invaluable for safety and compliance across a number of industries, including:

Manufacturing: Matroid proactively identifies hazards on production lines, guaranteeing equipment operation complies with safety standards and prevents accidents.

Transportation: Matroid can monitor vehicle conditions and driver behavior, identifying fatigue-related signs to comply with safety regulations and reduce accident risks.

Aerospace: Matroid’s CV monitors equipment health, establishing compliance with maintenance protocols and detecting anomalies during pre-flight checks.

Airport Management: Matroid’s end-to-end platform enhances security by monitoring baggage handling, identifying security breaches, and adhering to safety protocols, thus fostering a safer airport environment.

Tap into the transformative capabilities of Computer Vision with Matroid’s platform and redefine workplace safety for improved efficiency and team well-being. See the technology in action, connect with our team of experts, discuss your unique challenges and objectives, and tailor the system to meet specific requirements—all without the need for coding—today.