Choosing the Right Visual Inspection Software for Your Manufacturing Needs

Matroid | October 30th, 2024

In the dynamic world of manufacturing, where success relies on precision and efficiency, visual inspection software has emerged as a cutting-edge tool. With the majority of manufacturers acknowledging the essential role of AI integration in staying competitive, visual inspection software powered by AI and computer vision stands at the forefront of this transformation. This guide offers a comprehensive roadmap for manufacturing professionals seeking to choose the right visual inspection software tailored to their unique needs, ensuring enhanced product quality and operational efficiency.

Understanding Visual Inspection Software

What is Visual Inspection Software?

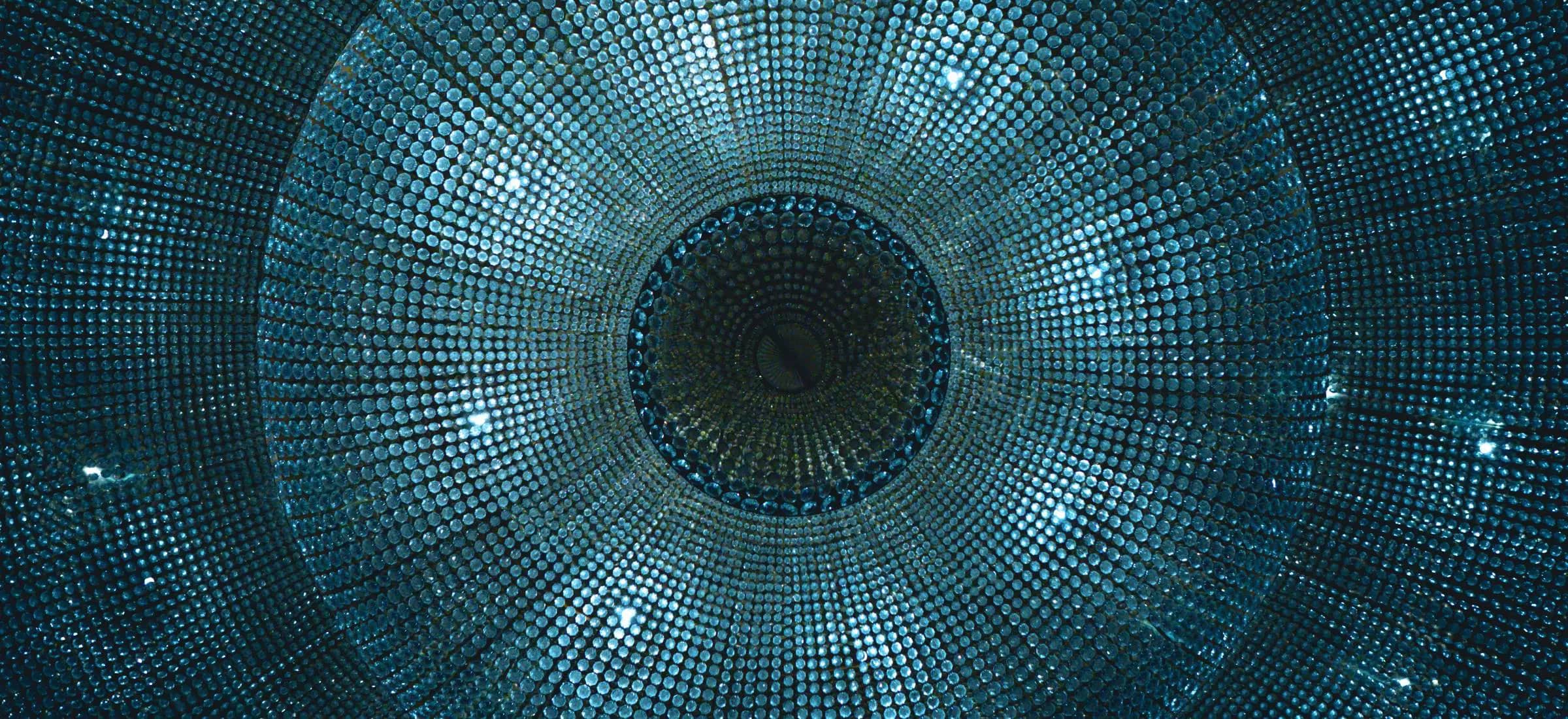

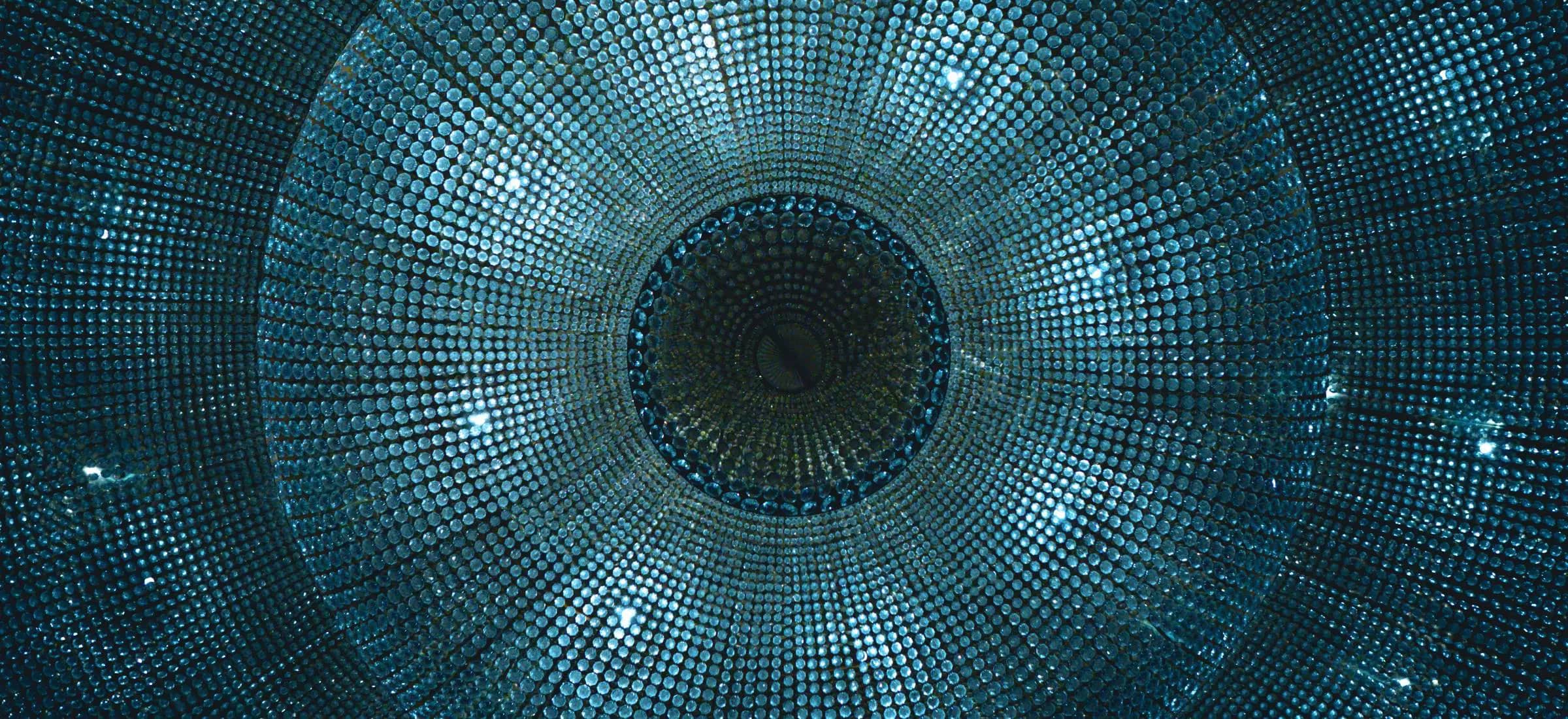

Using artificial intelligence (AI), machine learning, and computer vision, visual inspection software automatically detects defects, anomalies, and quality issues in manufacturing processes. This technology identifies problems that human inspectors or traditional quality control methods might overlook by analyzing images or video feeds in real-time. Key components include image capture devices like cameras and sensors, AI algorithms for image processing, user-friendly interfaces, and integration capabilities with existing manufacturing systems.

Visual Inspection in Manufacturing

Visual inspection software is a cornerstone of modern quality assurance in the manufacturing industry, enhancing efficiency and safety. This cutting-edge technology is a powerful asset in automotive manufacturing, where it diligently uncovers powertrain precision issues, detects defects in stamped parts, and evaluates weld quality with unparalleled accuracy.

In the metal forming sector, the software excels in identifying incomplete fills, long cracks, and transverse cracks in slabs, all while recognizing potential safety hazards, ensuring higher standards of production reliability, and ensuring worker safety. Its integration drives the manufacturing sector forward, setting new benchmarks for defect detection and process optimization, ultimately leading to superior product integrity and operational excellence.

Key Considerations for Choosing Visual Inspection Software

Selecting the right visual inspection software requires reviewing multiple factors to ensure optimal performance and business outcomes.

Precision

At the core, the software must offer new levels of precision in defect detection to maintain high product quality standards and avoid the pitfalls of false positives or negatives. This accuracy drives high customer satisfaction standards, adhering to regulatory requirements and ensuring dependable inspection results under diverse conditions.

Efficiency

Improving workflow efficiency is another important piece. The software should enhance the quality control process by significantly reducing manual inspection time and minimizing waste. Enabling continuous automated inspection processes enables prompt interventions, alleviating production bottlenecks.

Scalability

As businesses grow, so should their technological solutions. The software must efficiently handle expanding production volumes while maintaining peak performance. Its adaptability to integrate with emerging technologies and feature easy customization options ensures it remains relevant across varied manufacturing settings.

Integration

The inspection software should effortlessly connect with manufacturing execution systems (MES) and enterprise resource planning (ERP) software. Simple implementation and comprehensive data management capabilities make for a cohesive operational environment.

User-Friendliness

An intuitive user interface is key because it can accommodate a wide range of technical expertise levels. No-code or low-code platforms simplify the creation and modification of inspection criteria. Comprehensive training materials and support services that further enhance the overall user experience should accompany these features.

Benefits of Implementing Visual Inspection Software

Quality Control

Visual inspection software significantly enhances defect detection, reducing error rates and improving product consistency. In automotive manufacturing, it ensures precision in critical areas like powertrain assembly and paint quality. In metal forming, it drives uniform quality in casting processes.

Cost Savings

By detecting defects early, visual inspection software reduces waste and decreases the need for costly rework. The financial savings achieved through increased throughput and reduced labor costs add to substantial ROI.

Compliance

A key benefit of visual inspection software is ensuring adherence to industry regulations. It provides consistent, documented quality control processes, aiding in regulatory audits and certifications.

Data Analytics

The software generates valuable data insights, enabling continuous process improvement and predictive maintenance. Data-driven decision-making supports a culture of constantly enhancing product quality and operational efficiency.

Matroid’s Unique Offerings

Innovative Technology

Matroid stands out with a no-code platform that equips users to create custom detectors without programming expertise. Its advanced deep learning capabilities enable real-time issue detection and adaptive learning for improved performance over time.

Customizability

Matroid’s platform offers tailored solutions across manufacturing sectors, including automotive and metal forming. Its flexibility allows users to adapt the system to unique production requirements and emerging technologies.

Integration

Seamless integration with existing camera systems and software ensures consistent implementation across manufacturing environments. Matroid’s compatibility with MES and ERP systems enhances overall efficiency.

Support and Training

Matroid provides comprehensive support services, including software updates and ongoing technical assistance. User education resources facilitate quick adoption and maximize the platform’s potential.

Conclusion

Choosing the right visual inspection software is integral to enhancing quality control, achieving cost savings, ensuring compliance, and leveraging data analytics. By considering key factors such as precision, efficiency, scalability, integration, and user-friendliness, manufacturers can make informed decisions that drive significant improvements in their operations.

Are you ready to revolutionize your manufacturing process? Request a demo of Matroid’s platform today and discover how you can enhance productivity, quality assurance, and customer satisfaction. Join us in leading the charge in innovation and take your company’s performance to the next level.

Download Our Free

Step By Step Guide

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today