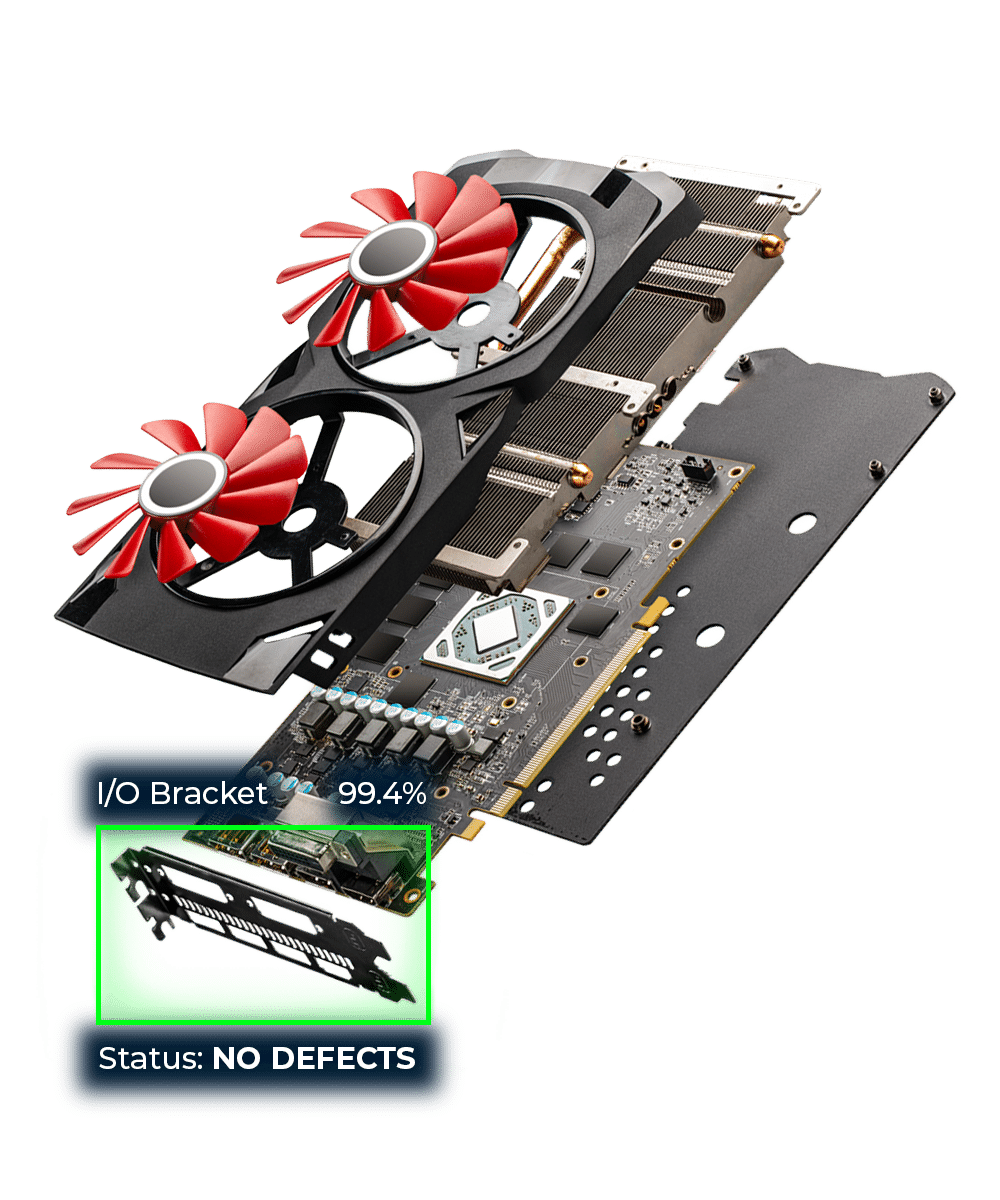

Industry Leading Quality Control, Automated by AI

Preemptively find novel defects, track production cycles, and exceed quality goals with automated visual inspection

Industry Leading Quality Control, Automated by AI

Preemptively find novel defects, track production cycles, and exceed quality goals with automated visual inspection

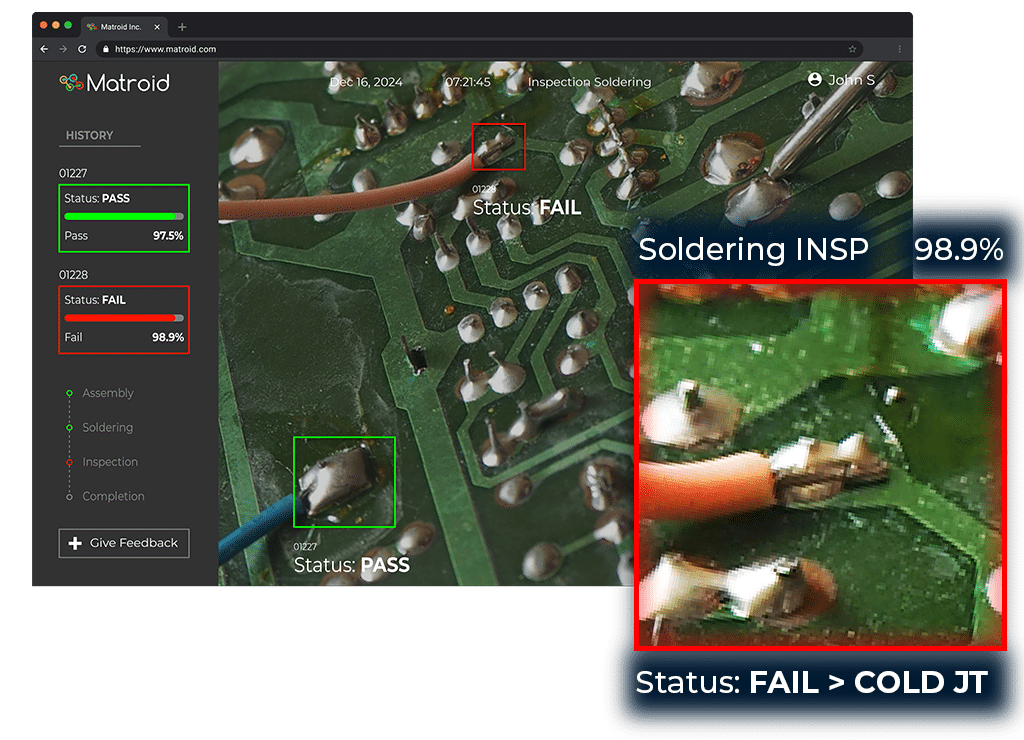

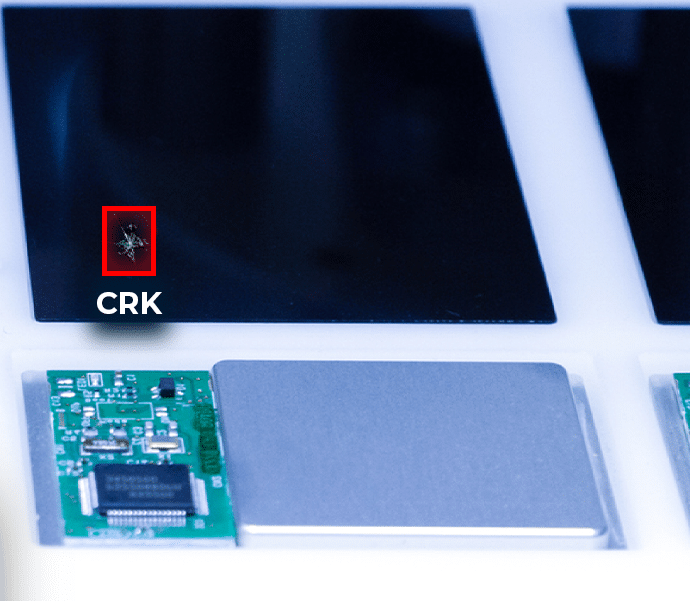

Precision Quality

Defect Detection

Built with your QA Expertise, Automated with our CV Knowledge. Leverage Matroid to ensure every product meets your rigorous quality standards. Start catching known production defects and find novel defects in minutes.

100%

Inspection > Complete

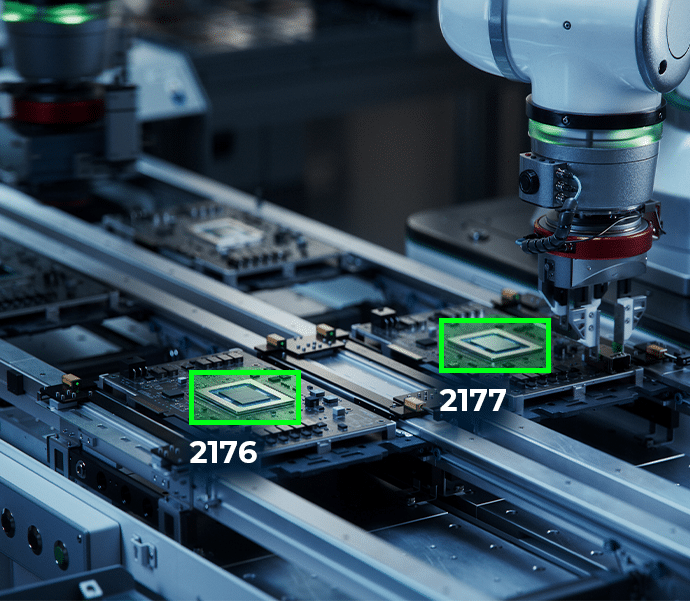

Cycle Analysis

Production Efficiency

Gather cycle time data across the production line and make it traceable, connected by serial numbers. Highlight deviations to leverage for line and production improvements, automatically.

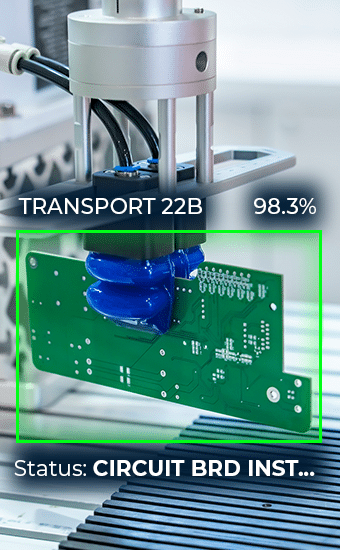

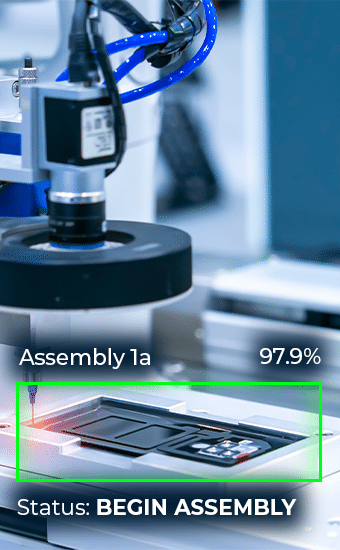

Process Optimization

Assembly Verification

Track and validate that every product, every batch, and every cycle follows SOP. Get notified instantly when mistakes occur. Save time spent on failure analysis by identifying assembly issues in minutes, automatically.

FAIL

Cracked Screen

Increase Profitability

Reduce Reworks & RMAs

Intercept defects in the assembly process. Enable automated early detection of issues, removing costly and time-consuming reworks and RMAs.

Scalability

Enterprise Growth

Scale and adapt to different operational needs and learn to recognize new patterns over time, making it a versatile tool for various applications.

Real-Time Alerts

Alerting & Notifications

Enable continuous monitoring of processes, providing instant alerts in case of deviations, allowing for immediate corrective actions.

sustainability

Minimize Waste

Promote greener manufacturing by optimizing resource consumption and minimizing waste, aligning operations with eco-friendly practices.

Real Success Stories from Our Customers

Discover the transformative power of our AI vision technology through the experiences of customers. Learn how manufacturers worldwide are achieving efficiency and safety with our cutting-edge solutions

Matroid enables us to rapidly deploy computer vision solutions to our manufacturing clients across Europe

David

Head of Digital Solutions

The visual cortex for your factory

Jonas

Digital Business Transformation, GIS

TRANSFORM YOUR ORGANIZATION WITH AI