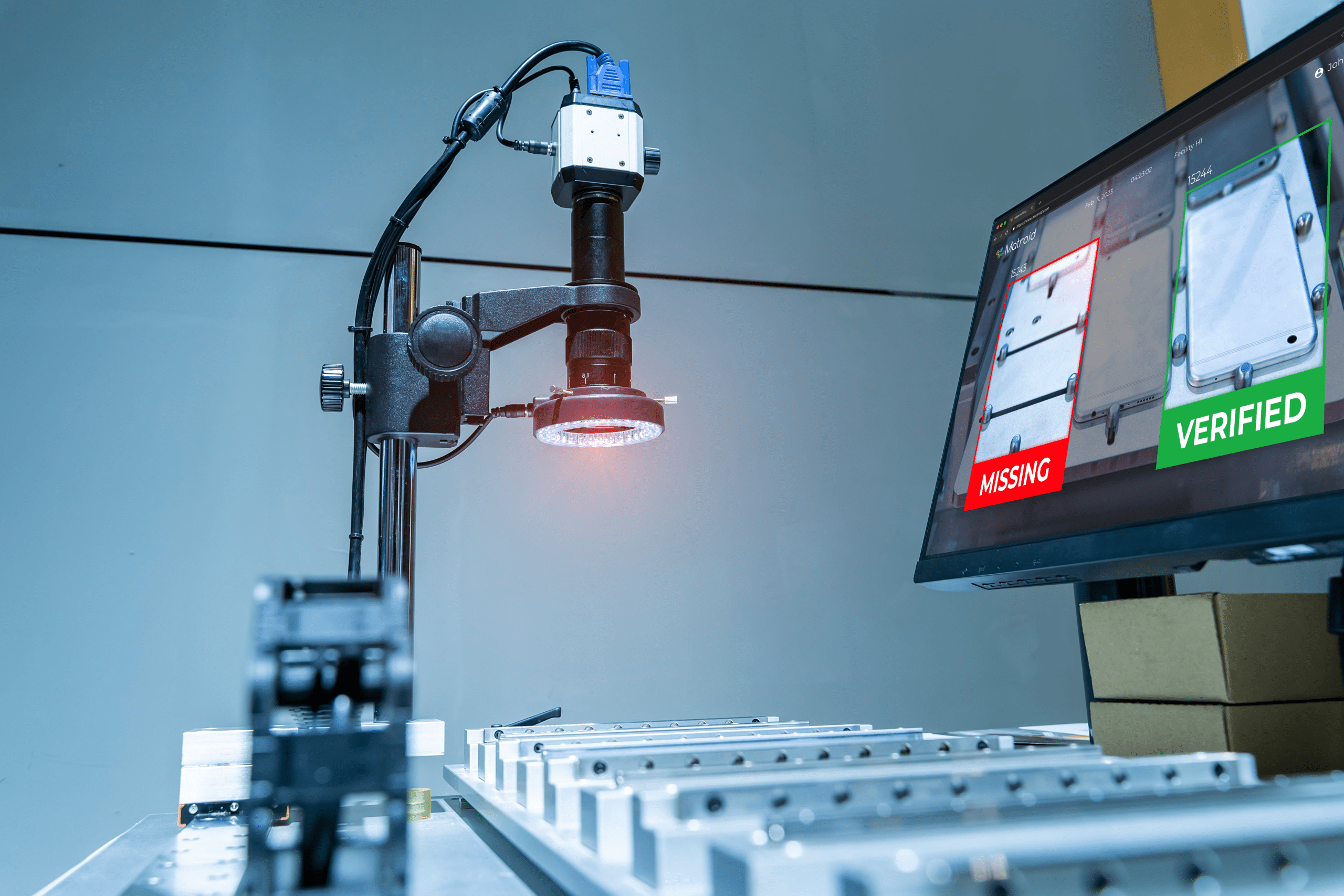

Optimize Manufacturing Operations with AI Computer Vision

Utilize the latest advancements in AI Computer Vision to automate visual inspections, drive zero-defects, improve SOP verification & cycle time analysis, and more.

Use Any Camera

Apply AI or (state-of-the-art-deep-learning) to any visual data - any camera, any resolution, any spectrum. Extract greater performance from your facility's existing camera infrastructure. Experience limitless options for any new application.

Detect & Classify Anything

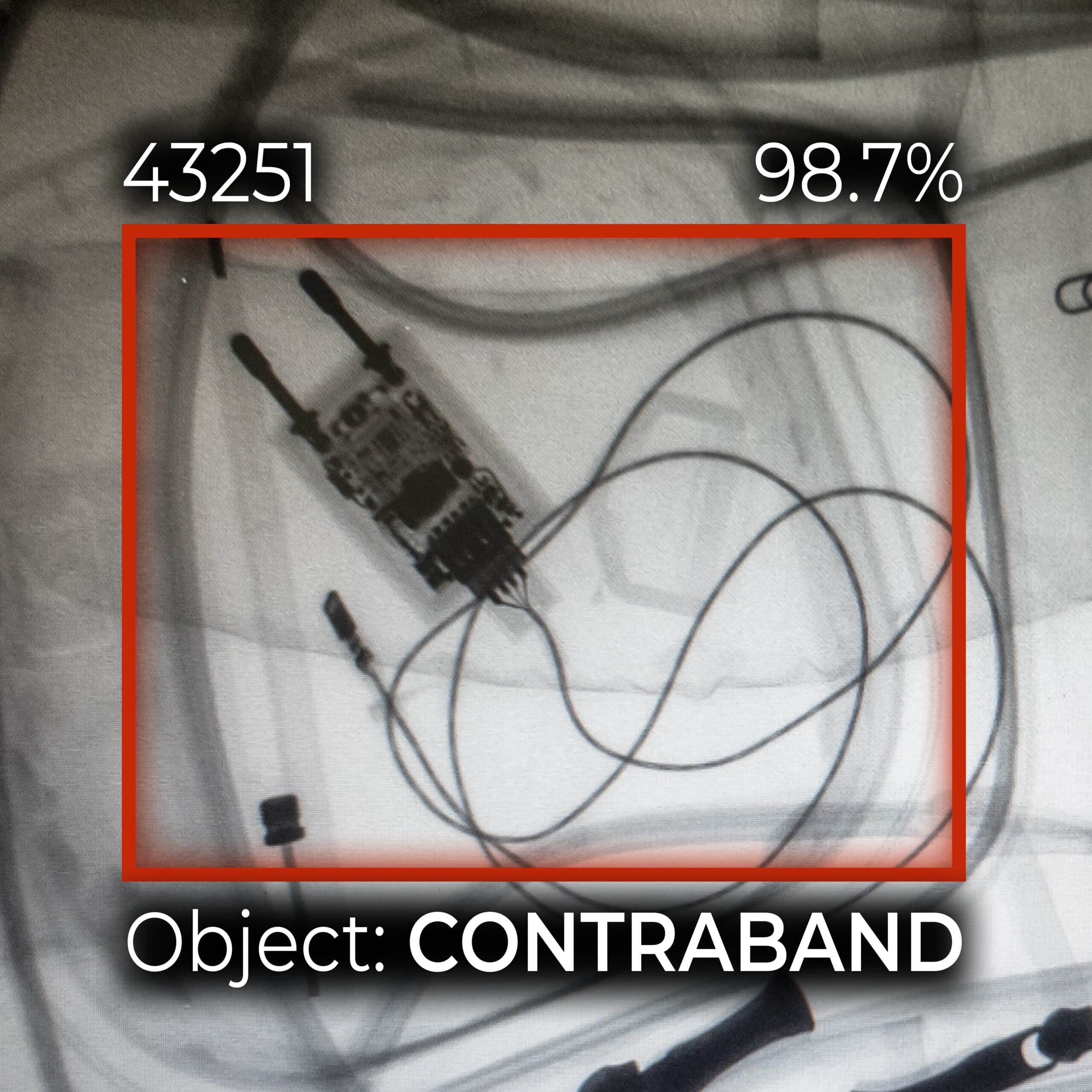

Say goodbye to limitations of inflexible, rules-based vision. Matroid’s Deep Learning AI uses proprietary neural networks to learn and improve over time. Precisely detect and classify defects, objects, assemblies, hazards, anything.

Monitor Any Process

Apply AI to video streams to detect, classify and quantify anything within. Ensure SOP conformance, monitor cycle times, detect hazardous events, send alerts based on your criteria, and harvest analytics for process optimization.

BREAKING THE "RULES"

What makes Computer Vision from Matroid completely different?

Traditional

"RULES-BASED" VISION

"Rules Based" Vision

- No defect insights

- Limited variation

- Limited tools (edges, contrasts, pixel counts)

- Rules-based programming

Matroid

COMPUTER VISION

Deep Learning

- Defect variations (shape, size, color, location, texture)

- Precise classification (faster to root cause)

- High mix production (product variations)

- Changing lighting conditions (24 hr production)

REQUEST MORE INFORMATION

We would be happy to share more information including real-world applications, success stories, integration & deployment options, and technical specifics.

Please provide us with some minimum contact information and we will follow-up to arrange an introductory discussion.

About Us

Making Computer Vision Accessible

At Matroid, we aim to accelerate AI, responsibly, through vision. AI is an ambitious, unsolved problem, so we're building a world class team with innovation and engineering excellence embedded into our culture.

Advanced USE CASES that only computer vision can solve

Defect Detection

Welding defects

Surface Defects

Micro Defects

Cycle Time Monitoring

Assembly

Zone Detection

Human Activities

Assembly Verification

Assembly Processes

Production Traceability

Shipping Procedure

Request A Demo Today

Let us show you how the power of computer vision can transform your organization