Eliminating Quality Defects in Industrial and Heavy Machinery with AI-Powered Computer Vision

Matroid | April 18th, 2025

Quality defects in industrial and heavy machinery manufacturing can be costly and damaging, leading to production delays, financial losses, and reputational damage. For manufacturers striving to maintain a competitive edge, ensuring the highest product quality is a top priority.

However, traditional quality control methods often fall short, hindered by human error and inflexible systems. This is where AI-powered computer vision transforms quality assurance practices with the ability to deliver unmatched efficiency, accuracy, and defect detection.

The Limitations of Traditional Quality Control

Traditional methods for ensuring manufacturing quality are complicated to implement and maintain when raw materials and large-scale assembly must be balanced with extreme precision. Manual inspections and conventional machine vision systems come with considerable drawbacks since human inspectors are susceptible to fatigue and distraction, no matter how skilled. Factors like mood or environmental conditions further exacerbate these inconsistencies, allowing defects to slip through the cracks and potentially advance into the production line.

While rule-based machine vision systems offer automation and faster inspection capabilities, they lack flexibility. These systems rely on predefined algorithms to detect specific flaws under controlled conditions. Minor changes — such as variations in lighting or assembly parts — often disrupt their accuracy. This lack of adaptability makes them poorly suited for the typical demands of industrial and heavy machinery manufacturing.

Additionally, industrial and heavy machine manufacturing can require production and assembly of enormously large parts. Many are often too big to rely on traditional machine vision systems. More advanced computer vision systems are much better suited to undertake quality control tasks at the scale needed in the industry as they combine the flexibility, precision, and learning necessary to monitor the industry’s most massive production lines successfully.

Quality Control via Computer Vision is a Better Solution

AI-powered computer vision can solve many problems that these traditional methods cannot overcome. Combining artificial intelligence with advanced image recognition, Computer Vision mimics human decision-making while significantly outperforming human-managed and rule-based systems.

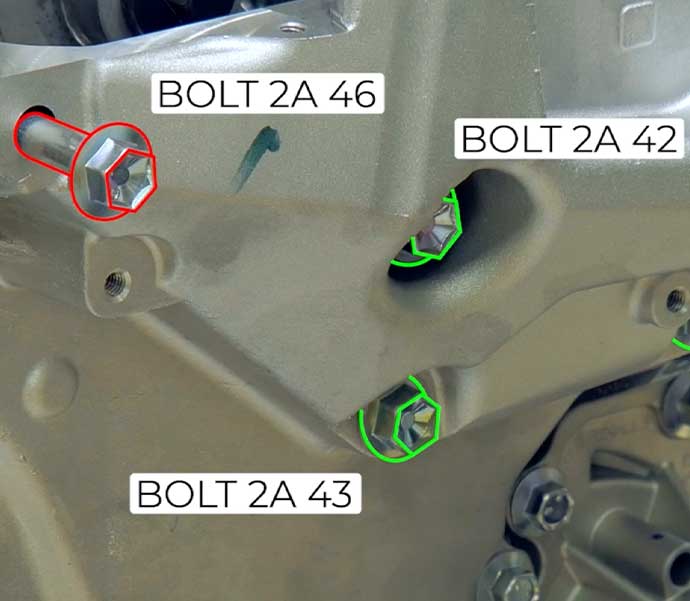

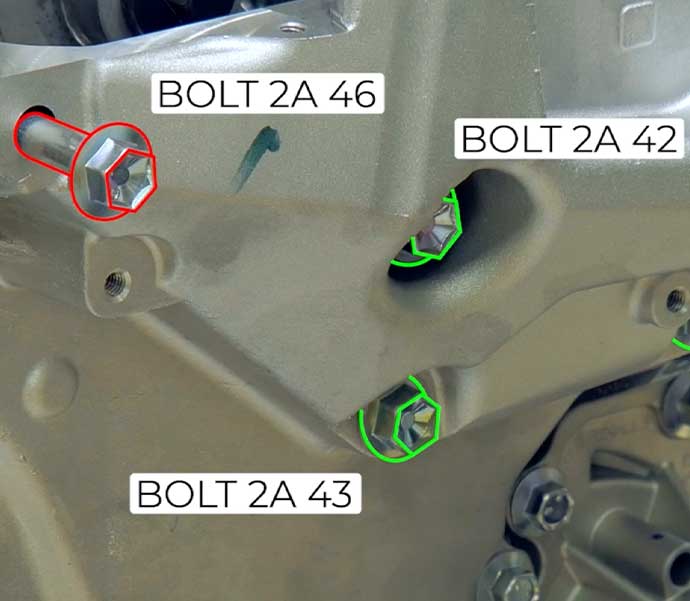

A significant advantage of AI-powered computer vision is its use of deep learning algorithms. These algorithms enable the system to process and analyze images by learning from examples. Instead of depending on rigid programming, AI systems train using a diverse set of images, allowing them to identify defects like missing washers, misalignments, or surface cracks. This learning process enables the model to detect flaws it has never “seen” before, making it highly adaptable and efficient.

These more advanced systems are also camera agnostic, allowing them to leverage non-traditional vision sensors when beneficial. Integrating the flexibility of a Go-Pro or security camera can increase the coverage area for inspections of large equipment or reduce the capital investment required to implement a new computer vision system by using existing equipment.

In addition, AI-powered vision systems excel in their ability to operate seamlessly in dynamic environments. Unlike rigid rule-based systems, these advanced solutions can handle changes in materials, environmental conditions, or production setups.

Speed and consistency are equally valuable benefits. These systems work tirelessly around the clock, unaffected by fatigue or distractions, ensuring every product is inspected with the same level of accuracy. The result is not just better quality control but also an overall smoother production process.

Computer Vision Technology in Manufacturing

AI-powered computer vision follows a streamlined yet robust methodology that makes it highly scalable for heavy machinery and industrial parts manufacturers. It begins with training the AI model using a comprehensive dataset of defective and non-defective components. Analyzing these examples allows the system to identify patterns and recognize potential flaws precisely.

Once trained, the technology integrates seamlessly with cameras on production lines, analyzing live video feeds to detect irregularities in real-time. Each potential defect is flagged immediately, enabling operators to take corrective action before the issue worsens or propagates downstream. Beyond identifying flaws, AI-powered systems deliver valuable insights through analytics, allowing manufacturers to proactively identify recurring problems, streamline workflows, and improve processes.

AI-powered computer vision is already revolutionizing the manufacturing industry with its diverse applications. Leading automobile manufacturers, including Mercedes and Yazaki, have adopted Matroid’s advanced computer vision technology to enhance their production processes. This implementation has streamlined quality control, reduced costs associated with defects, and ultimately improved the overall quality of vehicles reaching consumers.

The aerospace and materials industries rely on AI-backed computer vision to detect flaws in steel and composite alloys, ensuring compliance with strict regulatory standards. Given the critical nature of aircraft production, including the meticulous assembly, maintenance, and inspection validation, any precision lapse can lead to severe consequences. The integration of advanced object detection is emerging as a crucial component in upholding the highest safety and accuracy standards.

Across manufacturers, welding operations benefit as well. AI and high-resolution cameras can assess welding quality by analyzing attributes like porosity and spatter, reducing reliance on manual checks.

The Benefits Go Beyond Flaw Detection

The advantages of adopting AI-powered computer vision are not limited to quality control. Its successful utilization also reduces manufacturing costs by minimizing waste, scrap, and rework while reducing the need for large inspection teams.

Real-time defect detection significantly accelerates error identification and mitigation, preventing costly recalls or disruptions. In addition, AI-powered systems contribute to safer work environments by identifying unsafe conditions and enabling proactive adjustments. A well-designed and AI-backed computer vision system identifies issues before they become problematic, moving manufacturers from reactive quality control to proactive quality management.

For organizations focused on operational excellence, the investment in AI-powered computer vision represents a strategic leap forward for quality control and overall productivity and competitiveness.

Matroid is the Future of Quality Assurance

The industrial landscape is increasingly complex, and manufacturers are under more pressure than ever to optimize processes, cut costs, and maintain impeccable product quality. AI-powered computer vision has emerged as an indispensable tool for achieving these goals.

Among the leaders in AI-powered computer vision, Matroid stands out for its innovative and accessible approach. Matroid offers a no-code platform explicitly designed for industrial applications, removing barriers for manufacturers without technical expertise. Its ability to refine production processes, drive efficiency, and deliver consistent quality fundamentally changes how manufacturers approach quality assurance.

One of Matroid’s key advantages is its versatility. The platform works seamlessly with any camera and can adapt to different lighting and environmental conditions, ensuring reliable defect detection across various manufacturing setups. Additionally, its real-time alert system flags defects immediately and provides actionable insights, empowering operators to make data-driven decisions.

Privacy is another crucial advantage of Matroid’s offerings. With built-in people anonymization, the platform ensures compliance with privacy standards while still delivering valuable footage for training and analysis. Most importantly, Deployment is quick and straightforward, making it easy for manufacturers to integrate Matroid into existing workflows and begin seeing results almost immediately. Take the necessary leap toward innovative and more efficient manufacturing and request a demonstration from Matroid today to explore how AI-powered solutions can transform your operations.

Download Our Free

Step By Step Guide

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today