Matroid’s AI Computer Vision: Shifting Gears in the Auto Industry

Matroid | October 14th, 2024

What if your manufacturing process could detect assembly line issues in real time, before they become costly problems? With Matroid’s AI-powered computer vision systems, this is now a reality. The unparalleled set of eyes that computer vision provides guarantees every component meets the highest quality and precision standards. Less downtime. Increased efficiency. Fewer disruptions. That’s what Matroid delivers.

Eighty-seven percent of manufacturers in a recent Fictiv survey agree that integrating AI into their processes is vital for future success. Automotive challenges like quality control and environmental regulations can drain time and resources. Computer Vision, enhanced by deep-learning, is one way to stay ahead of the curve, reshaping car manufacturing to ensure vehicles are safer, more reliable, and built to the highest standards.

By adopting Matroid’s computer vision, auto manufacturers can turn the tables, optimize processes, and reinforce their competitive stance in a crowded global market. Here’s how Matroid’s CV is advancing the automotive industry – by solving critical problems and elevating automobile manufacturing

How Matroid’s CV Tackles Core Manufacturing Issues

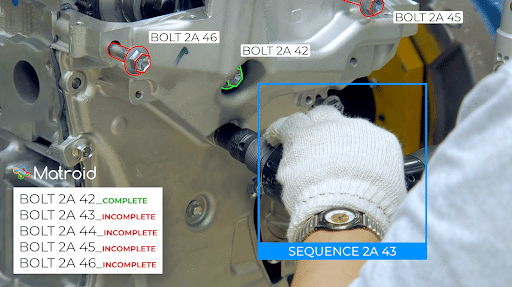

Powertrain Precision

Problem: The powertrain, which includes engines, transmissions, and control systems, often suffers from defects and assembly issues. These problems, along with SOP compliance failures, lead to lower quality, increased errors, and slower production.

Matroid’s Solution: Matroid’s visual defect detection system addresses these problems head-on by spotting imperfections and ensuring precise assembly. It enforces SOPs, guarantees regulatory compliance, and speeds up production cycles. That makes for a faster, more reliable process that doesn’t sacrifice top-notch quality.

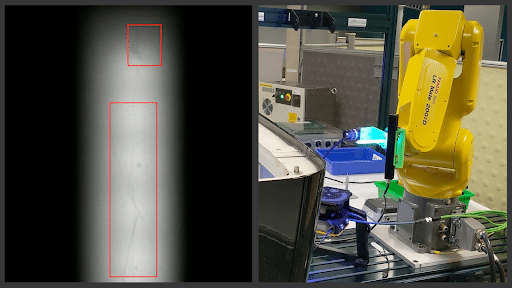

Flawless Stampings

Problem: During stamping, when metal parts for vehicles are shaped and formed, the parts can develop defects like holes, splits, and tears. Now what? Costly rework and compromised product quality.

Matroid’s Solution: Matroid’s easy-to-use computer vision system scans each stamped part for defects, only allowing the flawless components to proceed. This eliminates the expensive prefixes and upholds the best quality in vehicle assembly

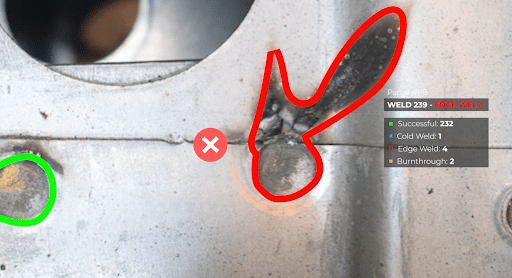

Top-Quality Welds

Problem: In body welding, joining metal parts using techniques such as spot, MIG/TIG, laser, and seam welding can result in problems like burnthrough, misalignment, porosity, and spatter. These issues compromise weld strength, safety, and overall quality.

Matroid’s Solution: Matroid’s computer vision system meets welding challenges by inspecting every technique: detecting burnthrough in laser welds, ensuring alignment and spotting issues in spot welds, verifying flawless seams in seam welds, and checking for porosity and spatter in MIG welds. Strong, reliable, and top-quality welds are the outcome.

Paint Flaws Eliminated

Problem: In painting, flaws like scratches, runs, and drops mar the finish, not to mention the aesthetic. Then there’s the time and expense to correct them.

Solution: Matroid’s AI computer vision system excels in scanning painted surfaces for defects, catching every imperfection to guarantee an unblemished finish. No expensive touch-ups are needed. Every vehicle exits production with a pristine look.

Plastic Defects Detected

Problem: Plastic components like trim, dashboards, and bumpers frequently face defects such as short shots and missing clips. These flaws hurt component quality and assembly accuracy, causing inefficiencies and increased cycle times.

Solution: Matroid’s computer vision system is ready to detect defects in all molding and extrusion processes, from injection molding to blow molding. It catches short shots and missing clips, ensures proper part placement, and checks the integrity of felt and foam. This streamlines assembly, cuts cycle times, and boosts production efficiency. The result? Superior plastic components.

Part Assembly Success

Problem: Vehicle part assembly faces hurdles in achieving precise component preparation, sub-assembly alignment, and overall quality control. Defects, incorrect dimensions, cleanliness issues, and assembly errors can hinder production and cost more money to fix.

Solution: Matroid’s computer vision revolutionizes assembly by automating component prep, detecting defects, measuring dimensions, and ensuring cleanliness. It offers precise sub-assembly alignment, verifies module specs, and monitors main assembly for accuracy. The real-time feedback for both robotic and manual processes makes for an error-free, streamlined assembly process.

Final Assembly Optimized

Problem: Final assembly before dealership delivery involves intricate tasks like precise installation, wiring, fluid filling, and cosmetic work. Errors like misalignments, defects, and malfunctions can compromise the vehicle’s readiness and quality.

Solution: Matroid’s computer vision redefines final assembly by ensuring precise installation of crucial components like engines and suspension systems. It performs detailed inspections to spot errors or defects in both interior and exterior parts, including misalignments, scratches, and missing components. CV also tracks electronic systems and sensors to identify and fix malfunctions during testing. Exterior finish to interior details are all part of the AI-enhanced once-over.

Impact of CV on ROI in Automotive Manufacturing

The impact of Matroid’s visual inspection system on ROI is profound. Automotive manufacturers who make the choice to implement computer vision software experience:

- Efficiency Gains: Optimized production processes and reduced cycle times.

- Quality Improvement: Higher standards and fewer faulty products.

- Cost Reduction: Minimized rework and waste.

- Improved Compliance and Standardization: Consistent adherence to SOPs and regulatory standards.

- Higher Customer Satisfaction: Defect-free vehicles that enhance brand reputation and foster loyalty.

Drive Automotive Innovation with Matroid’s Computer Vision

As the automotive industry gears up for a promising year ahead, Matroid’s computer vision software stands as a secret asset, ready to tackle manufacturing challenges with unprecedented precision. Continued advancements in AI promise even greater integration of CV into every stage of production, offering more accuracy, efficiency, and adaptability.

Are you ready to revolutionize your manufacturing process? Request a demo of Matroid’s CV today and discover how you can drive significant improvements in productivity, quality assurance, and customer satisfaction. Join us in leading the charge in automotive innovation and enhance your company’s performance.

Building Custom Computer Vision Models with Matroid

Dive into the world of personalized computer vision models with Matroid's comprehensive guide – click to download today